Service Hotline

+15081498285

(AEM、ACM)

This is the most widely used material for oil seals, which has good heat resistance, oil resistance, salt solution resistance, hydraulic oil resistance, and gasoline resistance. Standard NBR has 38% ACN (acrylonitrile). It can also work in a dry environment, but it has a time limit. Its disadvantage is that it does not use chemicals. The higher the ACN content, the better the resistance to solvents, oils, wear resistance, and higher temperatures. The lower the relative ACN content, the better the performance of low temperature resistance, but the solvent, oil, and wear resistance will also be relatively poor. We can provide different grades of NBR formulas for different application environments to meet the needs of customers.

Temperature range: between -35 degrees Celsius and 100 degrees Celsius (can withstand up to 120 degrees Celsius for a short period of time)

Hardness: Shore A 50 to 90 degrees

Color: Regular black, can also be specified by the customer. Application: Nitrile rubber is widely used in various oil resistant situations. Various oil resistant gaskets, seals, rubber hoses, hydraulic and pneumatic industry seals, cushioning pads, and other oil resistant and wear-resistant rubber parts are used for electronic fuel injectors in automobiles.

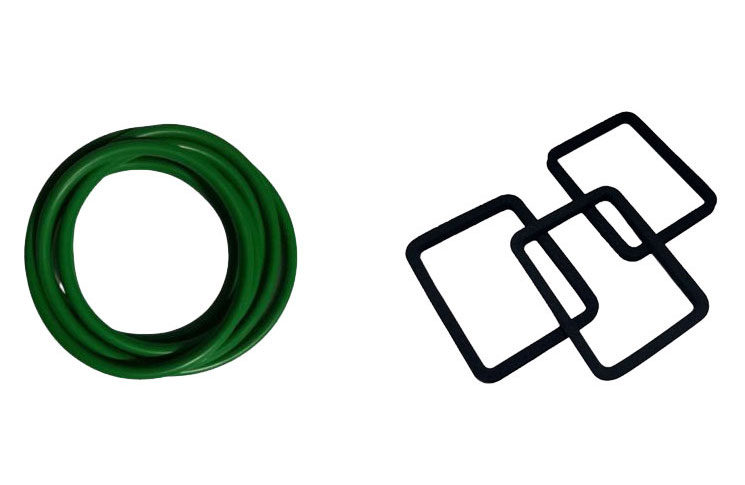

(Ethylene Propylene Diene Monomer,FFKM)

The more common name for fluororubber is Viton produced by DuPont. To meet the needs of special environments, fluororubber also has different formula options (copolymer& Ternary copolymer refers to fluorinated rubber with a fluorine content of 66%; Excellent resistance to chemical substances such as oil and high performance up to high temperatures. Contains 68% ternary copolymer gas rubber; Has relatively high resistance to fluids. Although FKM products are quite excellent, their prices are also quite high.

Temperature range: -25 degrees to 200 degrees

Hardness range: Shore A 50 degrees to 90 degrees

Color: Typically black/brown/green, but can also be specified by the customer. Application: Due to FKM's excellent properties of high temperature resistance, oil resistance, solvent resistance, flame resistance, chemical resistance, and weather resistance, it is commonly used in the automotive industry, chemical field, aerospace, and many other industries.

(Ethylene Propylene Diene Monomer,EPDM)

Ethylene copolymer with a methyl acrylate content of 8% to 40%, a milky white semi transparent solid. Due to its unique structure, it possesses many excellent characteristics such as heat resistance, aging resistance, oil resistance, ozone resistance, UV resistance, etc. Its mechanical and processing properties are superior to fluororubber and silicone rubber, and its heat resistance, aging resistance, and oil resistance are superior to nitrile rubber. ACM has been widely used in various high-temperature and oil resistant environments and has become a sealing material that the automotive industry has focused on developing and promoting in recent years, especially for high-temperature resistant oil seals, crankshaft valve stems, cylinder gaskets, hydraulic oil pipelines, etc. used in automobiles.

Operating temperature: -30 ° C to 150 ° C (short-term resistance to 175 ° C) Hardness range: Shore A 45 ° C to 80 ° C

Color: Typically black, but can also be specified by the customer

Application: AEM is usually used in situations where higher performance requirements are needed than nitrile rubber and chloroprene rubber, or where the cost of using high-end rubber (such as fluororubber) needs to be reduced. Mainly used for manufacturing seals for automotive engine oil and transmission oil.

(Ethylene Propylene Diene Monomer,EPDM)

Perfluoroether rubber material is composed of TFE (main chain), PMVE (branch chain), and bridging parts. It not only has high temperature resistance and chemical corrosion resistance, but also has the elasticity of rubber, which can maintain its elasticity and rebound performance in direct contact with corrosive fluids.

Temperature range: -15 degrees to 320 degrees

Hardness range: Shore A 60 to 90 degrees

Color: White, Black, Transparent, etc

Applications: Used in the petroleum and chemical industry, semiconductor process applications, food and pharmaceutical industry applications, aerospace, etc.

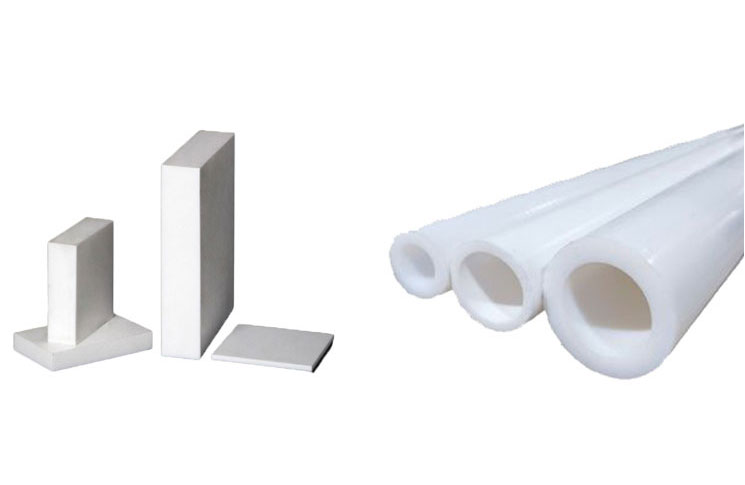

(Poly Tetra Fluoro Ethylene, PTFE)

Ethylene propylene diene monomer (EPDM) has various characteristics, including excellent aging resistance, corrosion resistance, and electrical properties; Due to its belonging to the polyolefin (PO) family, EPDM rubber has excellent vulcanization properties. The aging resistance of EPDM rubber is excellent. It can resist the effects of ozone, ultraviolet radiation, and other environmental factors, has good weather stability, and can maintain good elasticity even at low temperatures.

Temperature range: -40 ° C to 120 ° C (can withstand temperatures of 150-200 ° C in a short period of time)

Hardness: Shore A 50 to 90 degrees

Color: Regular black, can also be specified by the customer

Application: Ethylene propylene rubber has a wide range of applications in the automotive industry. It can be used to make automotive diaphragms, cups, dust covers, brake components, radiators, water tanks, engine connecting hoses, shock absorbers, and door and window seals. Ethylene propylene rubber can be used as a waterproof material when combined with asphalt in the construction industry. It can be used to make shock-absorbing products in the bridge industry, plastic steel door and window seals for high-rise buildings, and rubber floor tiles for indoor use. Ethylene propylene rubber can be used as an insulation material for transformers and can also be made into other high, medium, and low voltage insulation products. Ethylene propylene rubber can be used to make various chemically corrosion-resistant products, such as acid, alkali, ammonia, chloride resistant lining, various rubber hoses, heat-resistant conveyor belts, gaskets, seals, etc.

(Nitrile Butadiene Rubber,NBR)

Polytetrafluoroethylene (PTFE) has the properties of high temperature resistance, corrosion resistance, non stick, self-lubricating, and excellent dielectric properties. Polytetrafluoroethylene is a fluorocarbon chemical with excellent chemical resistance and resistance to high and low temperatures. It will not deteriorate even when exposed to air. Due to the presence of electron withdrawing groups of fluorine atoms in its molecular structure, PTFE exhibits high chemical stability and is almost resistant to the invasion of all acidic and alkaline chemicals; Outstanding non adhesiveness, abnormal lubricity, excellent electrical insulation performance, aging resistance and radiation resistance, extremely low water absorption rate, and other characteristics.

Temperature range: -200 ° C to 260 ° C

Hardness range: Shore A 55 degrees to 65 degrees

Color: Conventional colorless, milky white, and can also be specified by customers. Application: PTFE raw tape has long fibers, high strength, and good plasticity and rolling properties. It can be completely sealed with a small pressing force, and is easy to operate and apply. It is more efficient when used on uneven or structurally precise surfaces, has good sealing performance, and can improve corrosion resistance, expanding its range of use.

(Fluororubber,FKM/FPM)

Silicone rubber has excellent properties such as heat resistance, cold resistance, dielectric properties, ozone resistance, and atmospheric aging resistance. The outstanding performance of silicone rubber is its wide range of operating temperatures, high thermal stability, and excellent resistance to ozone aging, oxygen aging, light aging, and weather aging. It also has excellent electrical insulation performance, mold resistance, and high breathability.

Temperature range: -60 ℃ to 225 ℃, special silicone rubber can reach high temperatures of up to 300 ℃ and low temperatures of up to -100 ℃. Hardness range: Shore A25 degrees to 90 degrees. Color: regular transparent color, black, can also be specified by customers. Application: Silicone rubber is widely used in modern industry, defense industry, and daily necessities. Conductive silicone rubber that can be used in the electronics industry, LCD display contact components, TV anode covers, etc; Silicone rubber heating strip and heating element can be used to control the working temperature of precision instruments and oil field pipelines. Widely used in the construction industry as a room temperature vulcanized silicone rubber adhesive material and filling for glass materials, as well as for sealing cement joints. Silicone rubber can also be used for sealing doors and windows. Silicone rubber is also an excellent material for household appliances and food industries due to its ability to be odorless, tasteless, and non-toxic. It is also widely used in aerospace and aviation industries, such as oxygen mask sealing switches, airtight seals, and shock-absorbing materials. Silicone rubber also has various applications in the pharmaceutical field, including medical device seals, implantable and non implantable artificial organs, medical devices, etc.